Inductive Kickback - The curious case of the fan that didn't

As I was testing and validating the Soldering Smoke Absorber’s electronics, I noticed a curiosity: The input terminals were mostly.. fine?

…As I was testing and validating the Soldering Smoke Absorber’s electronics, I noticed a curiosity: The input terminals were mostly.. fine?

…

This is a fan that takes a carbon filter cartridge. It’s used to redirect the fumes encountered during electronics soldering.

…Backstory: I’ve been maintaining a build of LEDE for the ESPRESSObin single board computer. Things have changed for the better, so its now time to sunset the build.

…I got a little lost, debugging KiCad!

…

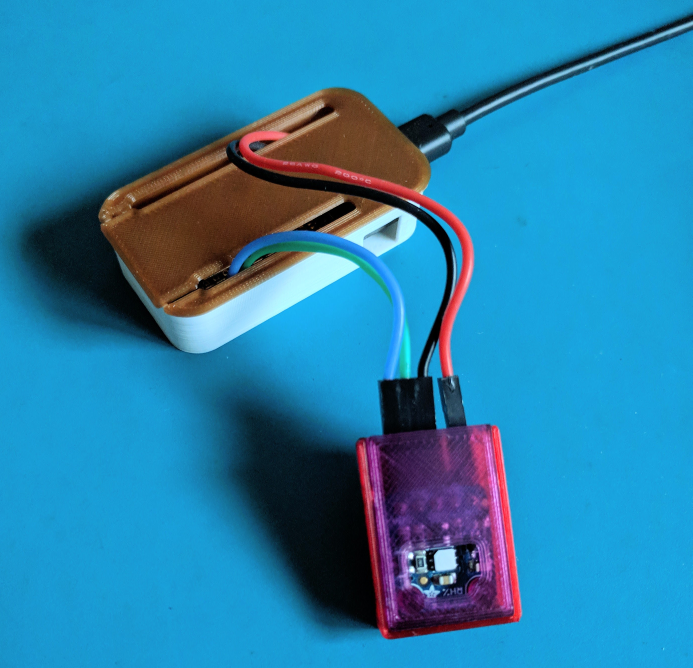

These are 3D printable cases for Adafruit’s Feather series of development boards. They’re designed to be compact, unobtrusive and adaptable from prototyping to deployment.

…

TL;DR: I made a modular Raspberry Pi camera case.

…The 9V attachable electroscope has been updated. The silkscreened date on the back for this version is 2014-08-24(!)

…